Docking vacuum suitcases

Vacuum suitcases can be docked at either endstation. In all cases:

the mounting port is CF40

for connection to UHV chambers (i.e. not the loadlocks) we provide a UHV gate-valve to the chamber and a short T-piece with pumping - only this intermediate section needs to be baked

the suitcase transfer arm must hold samples by the tag when presenting them to the receiving stations

the suitcase mounts horizontally

there is ample space - suitcase lengths of at least 2m will fit.

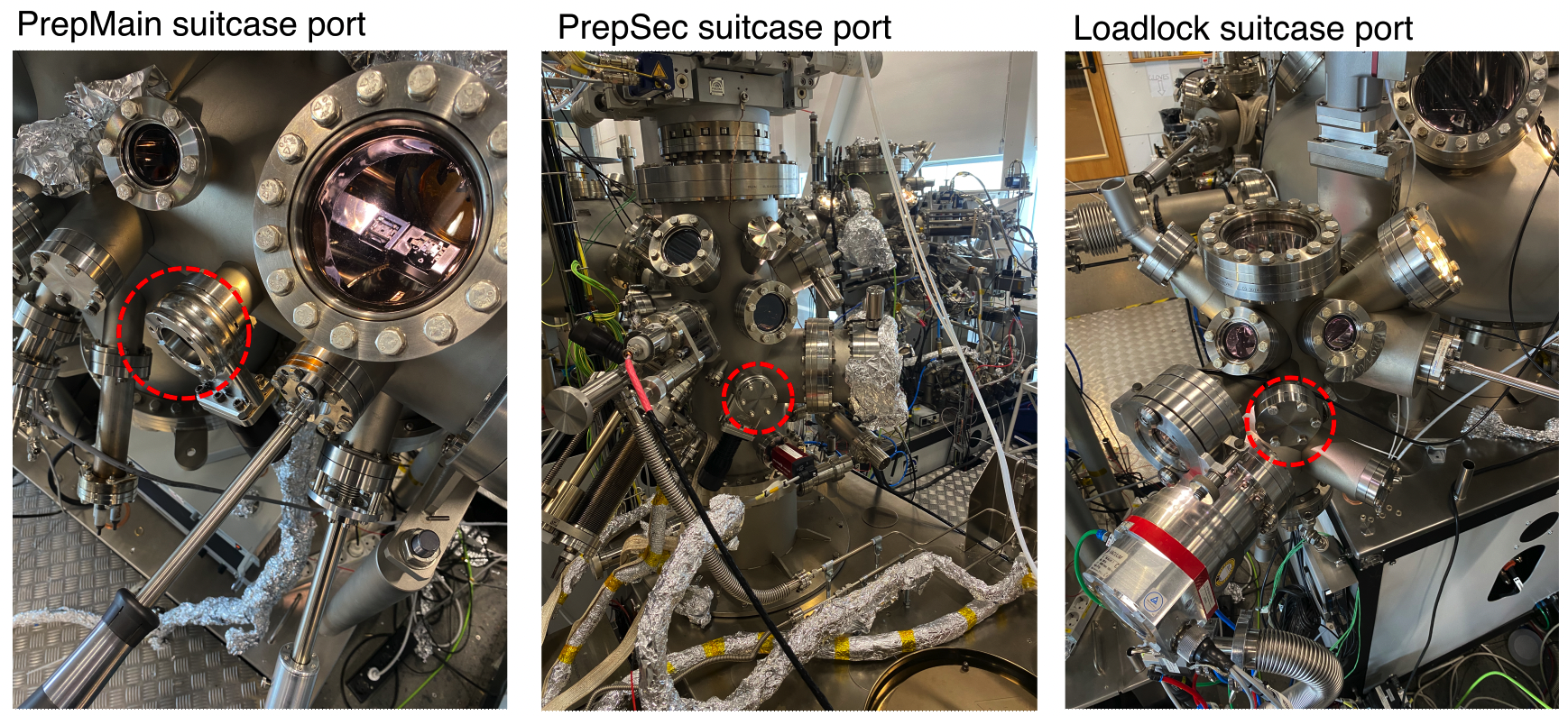

A-endstation (HR-ARPES)

Prep main (1e-10mBar)

Samples are loaded directly on to the 4-axis manipulator, so some misalignment can be tolerated

The transfer arm must have sufficient stroke for the center of the sample plate to extend 250mm past the last flange of the suitcase gate-valve. This is a conservative estimate, contact beamline staff if your suitcase stroke is close to this limit.

The small connecting T-piece is typically baked for 6-12 hours. Fans are available to keep the suitcase cool. Water lines are available if the suitcase incorporates water cooling.

Prep sec (1e-10mBar)

Samples are loaded directly on to the vertical 4-axis manipulator, so some misalignment can be tolerated

The transfer arm must have sufficient stroke for the center of the sample plate to extend 235mm past the last flange of the suitcase gate-valve. This is a conservative estimate, contact beamline staff if your suitcase stroke is close to this limit.

The small connecting T-piece is typically baked for 6-12 hours. Fans are available to keep the suitcase cool. Water lines are available if the suitcase incorporates water cooling.

Loadlock (<5e-9mBar if baked)

Samples are loaded on to the 6-slot carousel. There is no possibility to adjust the carousel height or angle, so your suitcase will very likely need some degrees of freedom on the transfer arm

The transfer arm must have sufficient stroke for the center of the sample plate to extend 100mm past the last flange of the suitcase gate-valve.

Unlike the preparation chambers there is no connecting T-piece - the loadlock is typically vented in order to attach or remove the suitcase.

For the best pressure the viton-sealed fast-access door should be replaced and the loadlock given an overnight bake with heating tapes

This is the usual attachment point for ‘inert-gas suitcases’, e.g. samples that have been transferred from a glovebox in an argon overpressure.

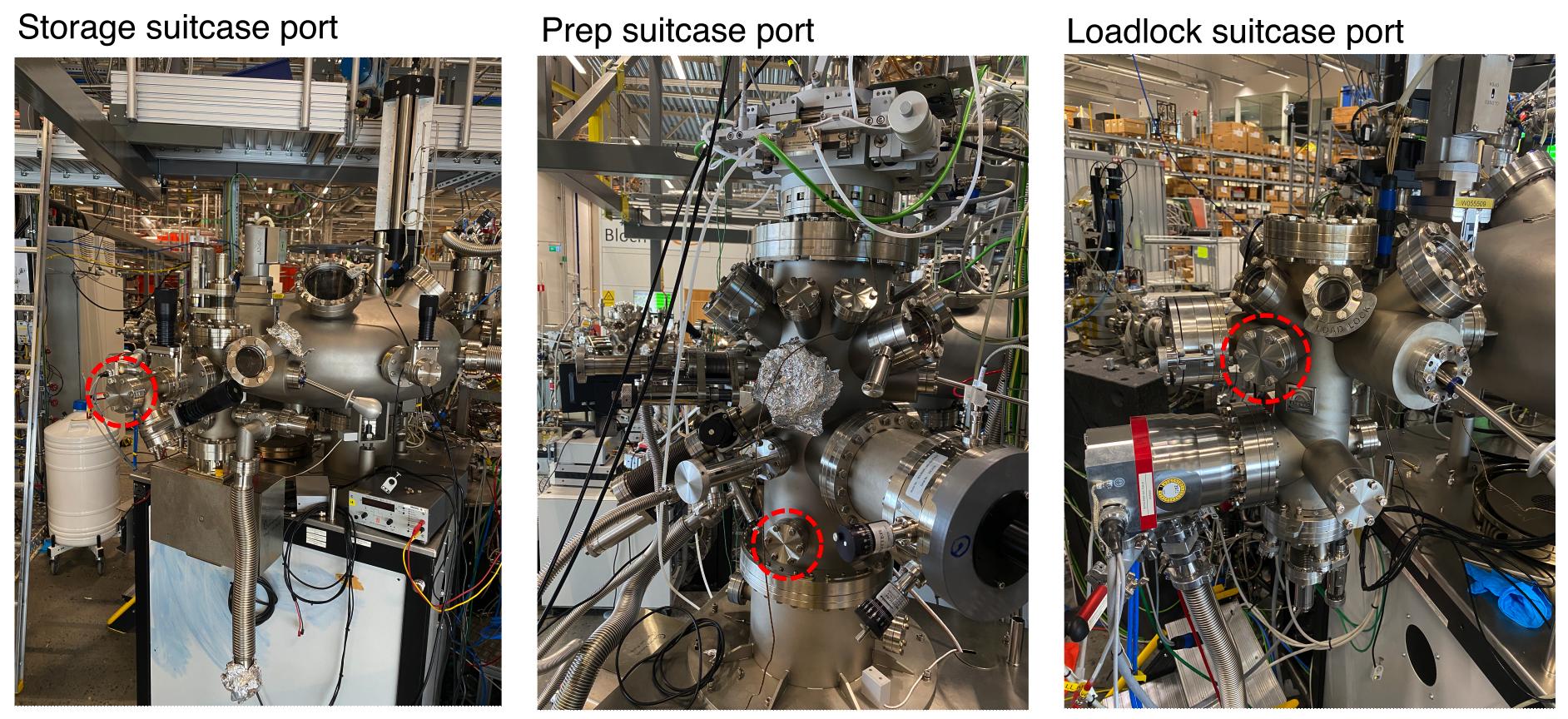

B-endstation (SPIN)

Loadlock (<5e-9mBar if baked)

Identical design and considerations as the A-endstation loadlock, except here the receiving carousel has vertical adjustment

Storage chamber (1e-10mBar)

Minimum stroke 250mm (if a short T-piece is installed). This is a conservative estimate, contact beamline staff if your suitcase stroke is close to this limit.

Preparation chamber (1e-10mBar)

Identical design and considerations as the A-endstation Prep sec chamber, except the gate-valve is not currently installed so a vent-bake cycle of the entire chamber is required - contact beamline staff well in advance if you think you will need this.