Loadlock

The loadlocks for both endstations have 6-slot carousels. While heating was originally possible in the loadlock, in 2023 the carousel was replaced with a simpler design that does a much better job at not dropping samples, but does not permit sample heating.

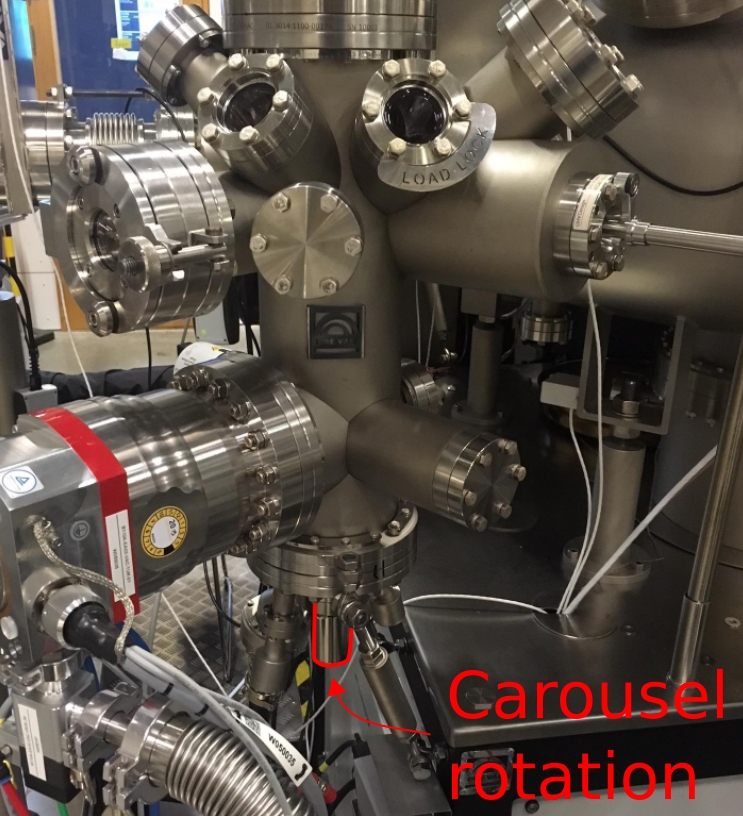

The carousel can be continuously rotated with a manual knob at the bottom of the chamber:

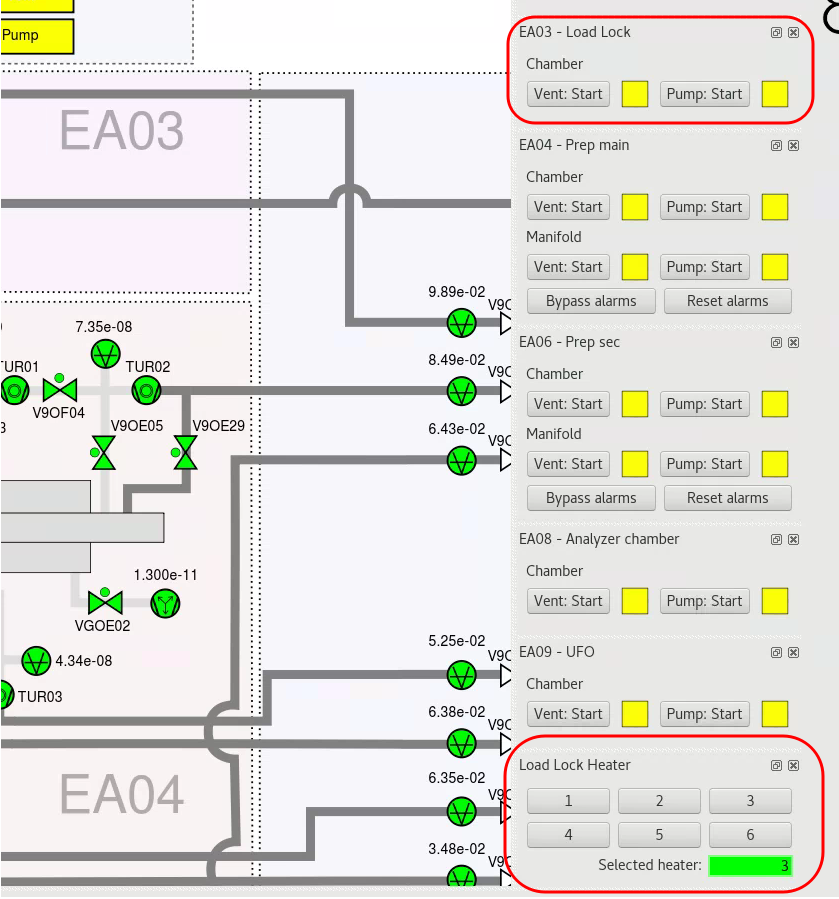

On the A endstation, venting or pumping the loadlock is a one-button task from the ‘ARPES Control panel’ window on the endstation PC

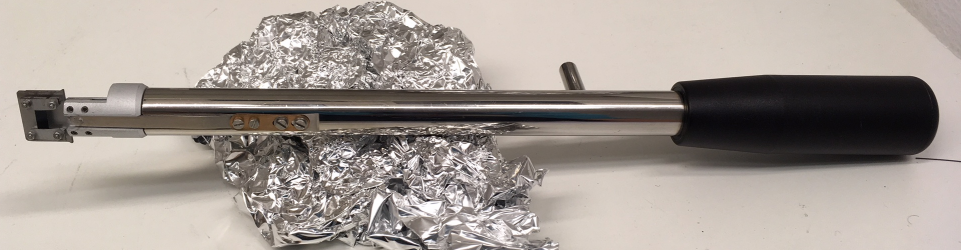

A special tool (shown below) is required to insert and remove samples via the viton-sealed door. It typically lives in the BLOCH workshop room. A staff member will show you how to operate it.

Pumpdown time

Pressure (mBar) |

Fast turnaround (hh:mm) |

Slow turnaround (hh:mm) |

|---|---|---|

1x10-6 |

00:15 |

00:30 |

1x10-7 |

2:00 |

3:50 |

1x10-8 |

22:00 |

?? |

Measured February 2019. Quick means only the amount of time necessary to insert a sample. Slow means opened, then left vented with door pushed closed for 30mins

Base pressure without baking: 6x10-9 mBar

We typically recommend waiting for a pressure of 5x10-7 mBar or better before opening to the transfer chamber, which you should obtain within 1-2 hours.